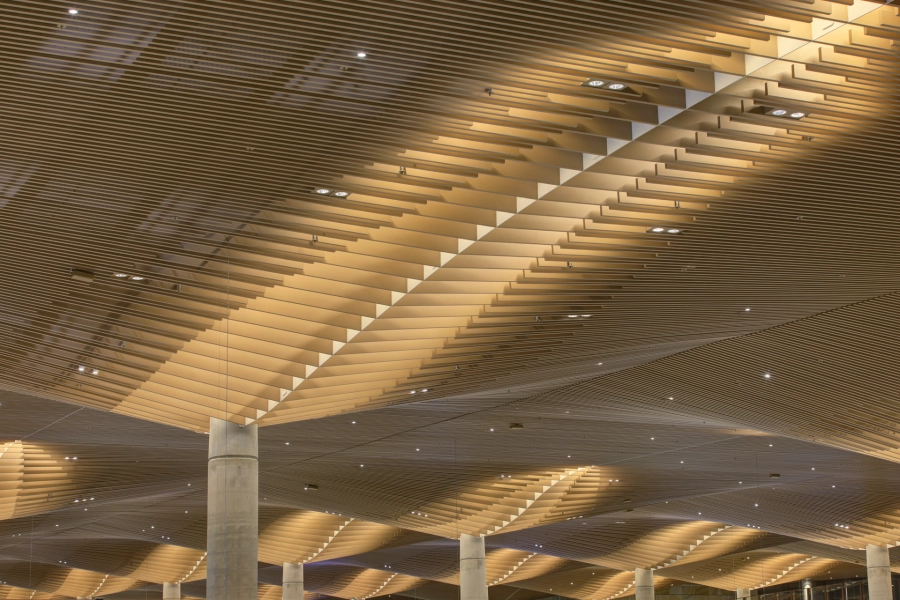

Case Study: Western Sydney International Airport

BackSeismic, prefabrication and vibration engineering solutions from KUSCH for Western Sydney International Airport.

Western Sydney International Airport brings together some of the world’s most respected design and engineering teams to deliver a project with national significance. The project was developed by Zaha Hadid Architects in partnership with Cox Architecture and Woods Bagot, combining global design capability with deep local knowledge. From its modular layout to its consideration for long-term sustainability and performance, the project sets a new benchmark for major infrastructure in Australia.

The airport is positioned to become a core economic and transport hub for Greater Western Sydney. Its delivery spans multiple disciplines and demands precise coordination across architecture, engineering, and construction. With a construction program spanning several years and involving extensive prefabrication, seismic engineering, and compliance requirements, the project called for specialists capable of solving complex problems at scale.

Images courtesy of Multiplex. Photographers Trevor Mein and Brett Boardman

KUSCH was engaged to deliver compliant, buildable and high-performance systems across multiple scopes and stakeholders. Our involvement with ECJV, Heyday Group, Vanderlande, RFI and Marley Flow required solutions across prefabricated services, seismic design and vibration isolation. Each solution was engineered to meet stringent codes while improving constructability and long-term system resilience.

Project Overview

- Client(s): Multiple (ECJV, Heyday Group, Vanderlande, RFI, Marley Flow)

- Location: Western Sydney Airport, NSW

- Scope Areas: Prefabricated services frames, seismic and pipework design, vibration mitigation

- KUSCH’s Role: Engineering partner across mechanical, electrical, and prefab scopes

Project Challenges:

The scale and complexity of the Western Sydney Airport project demanded a high level of coordination, compliance, and performance.

- Coordination with multiple clients and contractors

- Strict seismic and fire compliance across all services

- Vibration control for sensitive mechanical equipment

- Prefabrication challenges including transport, lifting, and fitment accuracy

Solutions Engineered by KUSCH

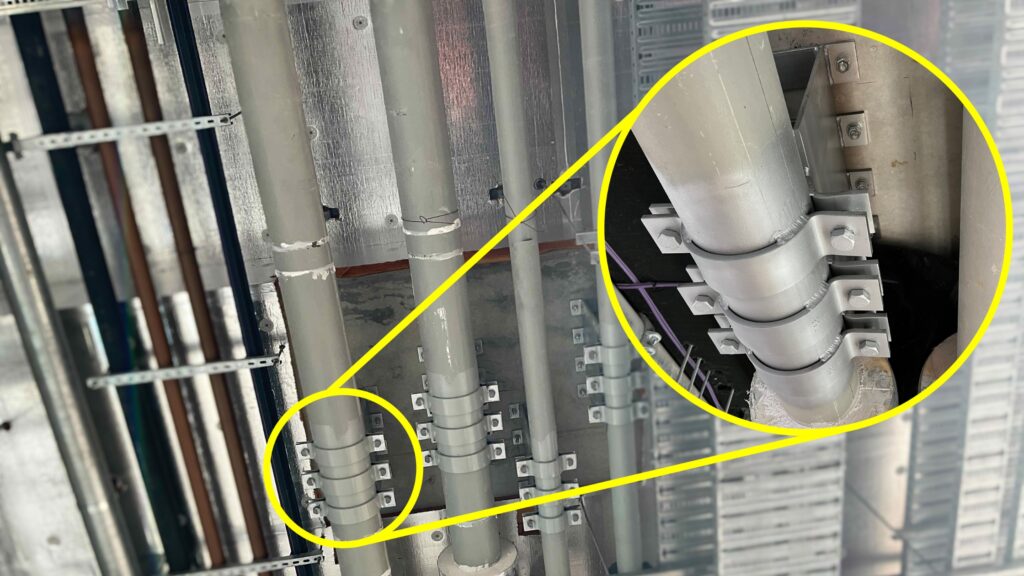

1. Prefabricated Services Frames

For ECJV, KUSCH designed prefabricated service frames that seamlessly integrated fire-rated insulation and seismic requirements. The frames were designed and modelled for precision in BIM to avoid site clashes and reduce install times. Each unit was engineered to meet structural lifting requirements and ensure installation accuracy.

2. Seismic Design of Mechanical Services

Our seismic engineers worked with ECJV to design mechanical service supports that met AS1170.4. KUSCH optimised restraint strategies, reducing unnecessary bracing while ensuring compliance.

3. Pipe Design for Building Movement

Pipe systems were designed for flexibility across building joints and long risers, accommodating thermal expansion and inter-storey drift. KUSCH engineered supports and anchors which allowed the pipe to grow thermally with slide guides and fixed anchors in appropriate locations. This mitigated the need for expansion bellows, so that pressure thrust forces weren’t induced, reducing the size and cost of anchors.

4. Seismic Design of Electrical Systems

KUSCH delivered seismic bracing solutions for Heyday Group, Vanderlande, and RFI. These included cable trays, switchboards, and control systems requiring secure anchorage and performance certification. We collaborated directly with site teams to ensure each design was practical and install-ready.

5. Vibration Isolation with Waffle Pads

Working with Marley Flow, KUSCH assessed and selected waffle pads for cooling tower installations, meeting stringent vibration performance requirements. This helped prevent operational fatigue in plant systems and ensured long-term resilience.

Results & Outcomes

- 40% reduction in on-site install time across prefab components

- AS1170.4 seismic compliance without over-bracing

- Improved coordination between services using BIM

- Reduced vibration impact and improved lifecycle performance of all services and systems.

Precision Where It Counts: KUSCH at Western Sydney Airport

From a distance, these solutions are almost invisible. Prefab frames, bracing systems, pipe anchors and waffle pads don’t grab headlines. But at Western Sydney Airport, these elements perform a critical role in shaping how the project came together on site; faster, safer and with long-term reliability considered from the start.

This project illustrates the power of smart, integrated engineering. Our work at Western Sydney Airport reflects our core vision: to build a better world through innovative and resilient engineering solutions that maximise value and minimise impact.

Capabilities Demonstrated

- Seismic Design (Mechanical & Electrical)

- Pipework Flexibility & Restraint

- Prefabricated Services Engineering

- Vibration Isolation Solutions

- Multi-client Coordination

Interested in learning how KUSCH can help you on your next project? Contact our team today.