Quay Quarter Tower, Sydney

BackEngineering Movement, Precision and Performance into Australia’s Most Ambitious Vertical Expansion

Quay Quarter Tower (QQT) represents a world-first in high-rise adaptive reuse. Located in Sydney’s Circular Quay, the project redefined what is possible in construction by retaining two-thirds of the original AMP Centre. The design, led by 3XN with executive architect BVN, demonstrates sustainable ingenuity and bold architectural thinking.

Delivering this vision required precision engineering. KUSCH was engaged by Equilibrium & Climatech JV Pty Ltd (ECJV) to provide design and certification for the mechanical and hydraulic risers. The project’s constraints included seismic compliance, inter-storey drift, and significant vertical spans, requiring integrated solutions tailored to movement, constructability and ongoing system performance.

Project Overview

Client: Equilibrium & Climatech JV Pty Ltd (ECJV)

Architect: 3XN (Design) / BVN (Executive Architect)

Builder: Multiplex

Developer: AMP Capital

Location: Circular Quay, Sydney NSW

Scope Areas: Prefabricated mechanical and hydraulic risers

KUSCH’s Role: Engineering design, movement analysis, prefabrication optimisation, seismic certification

Project Challenges

- Integration between retained and new structures, with complex movement behaviours

- Continuous services risers up to 150 metres in height

- Building movement from thermal expansion, core shortening and seismic drift

- Safety and space limitations within CBD shaft installations

- Need for coordinated delivery in a high-traffic, high-precision construction zone

Solutions Engineered by KUSCH

Modular prefabricated risers

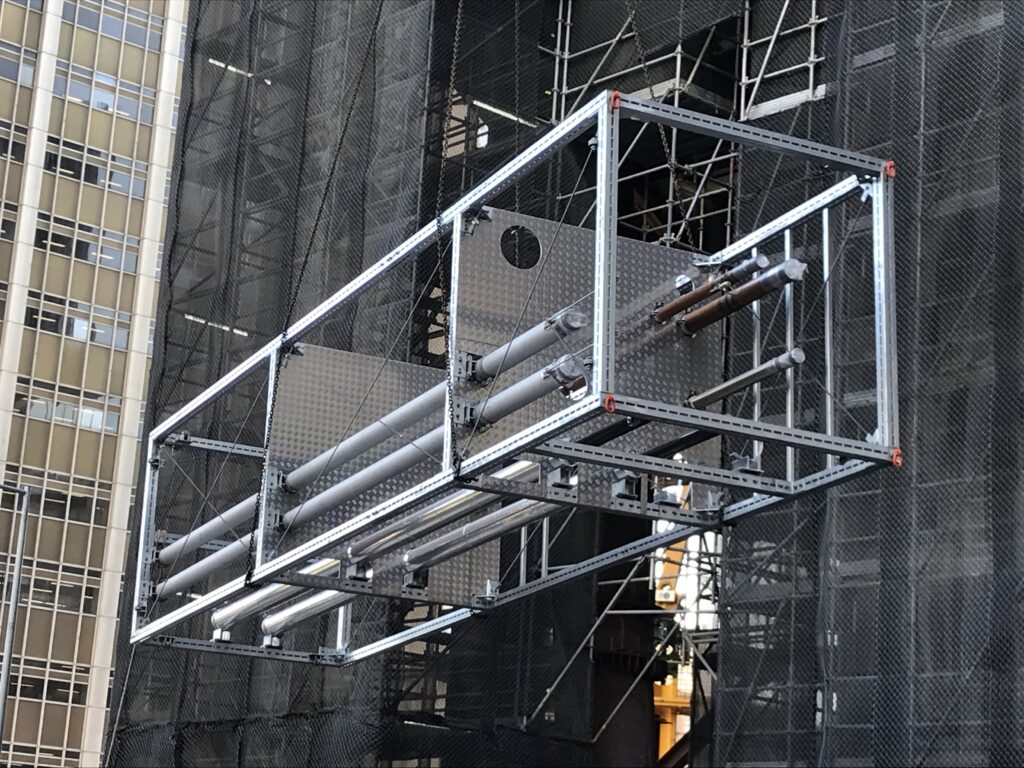

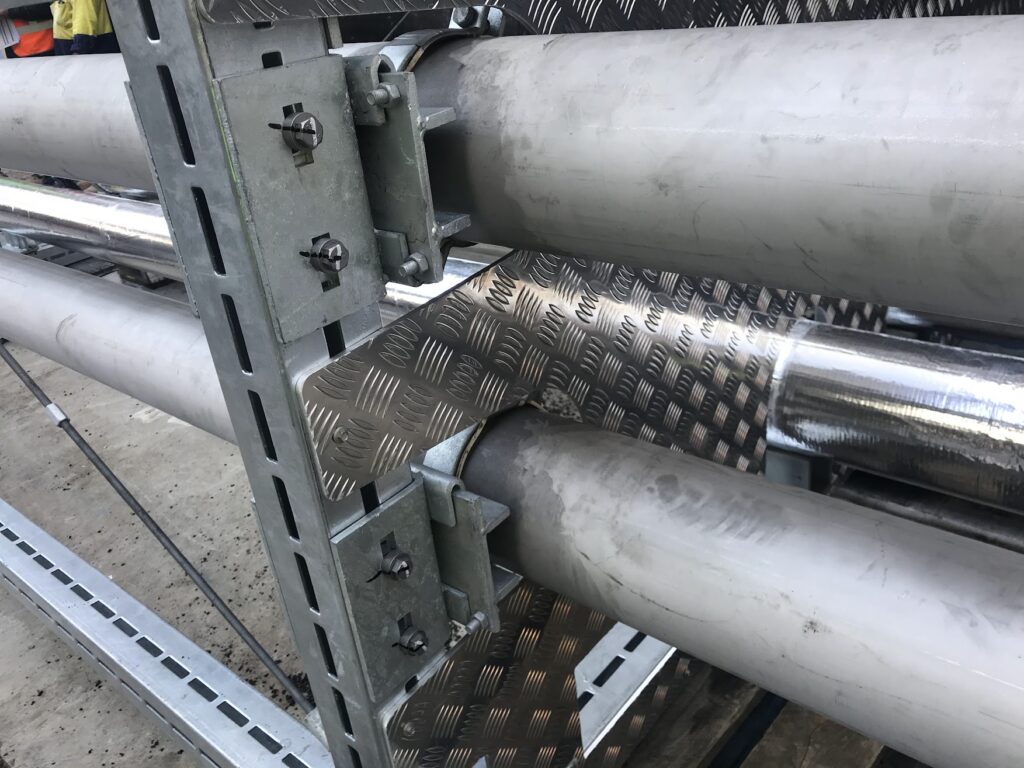

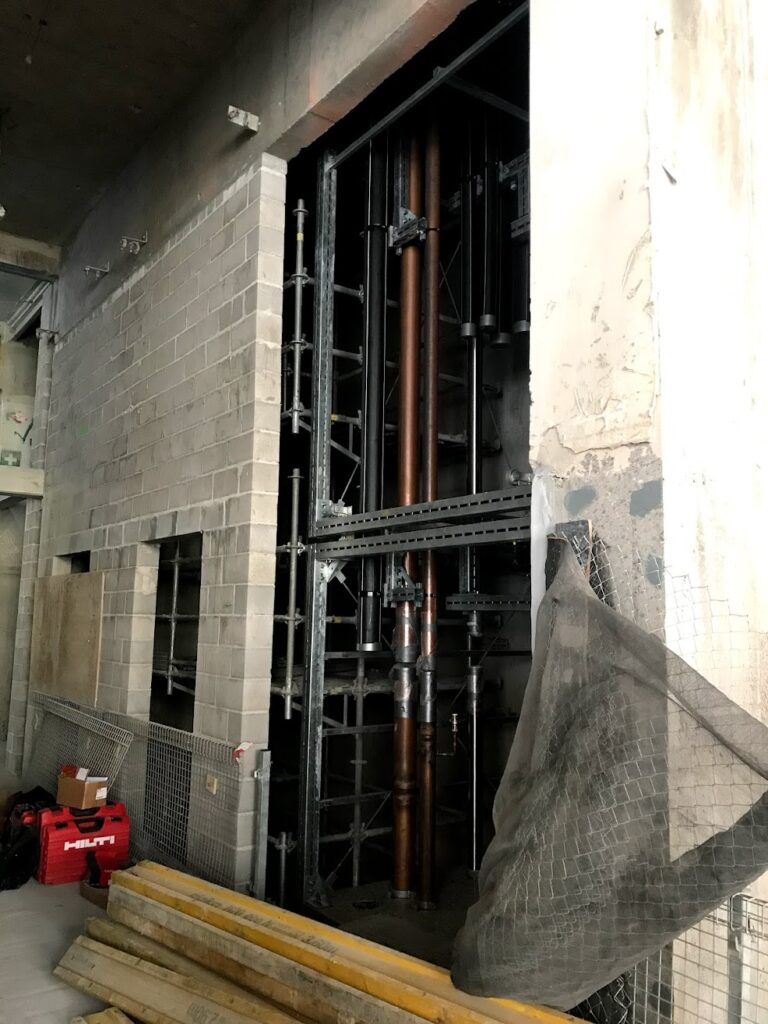

KUSCH designed modular prefabricated riser frames using sophisticated CAD techniques to enable BIM coordination, clash detection and off-site fabrication. Weld-free SUPA framing was used to streamline installation and eliminate on-site welding. Access platforms were incorporated to improve post-install maintenance.

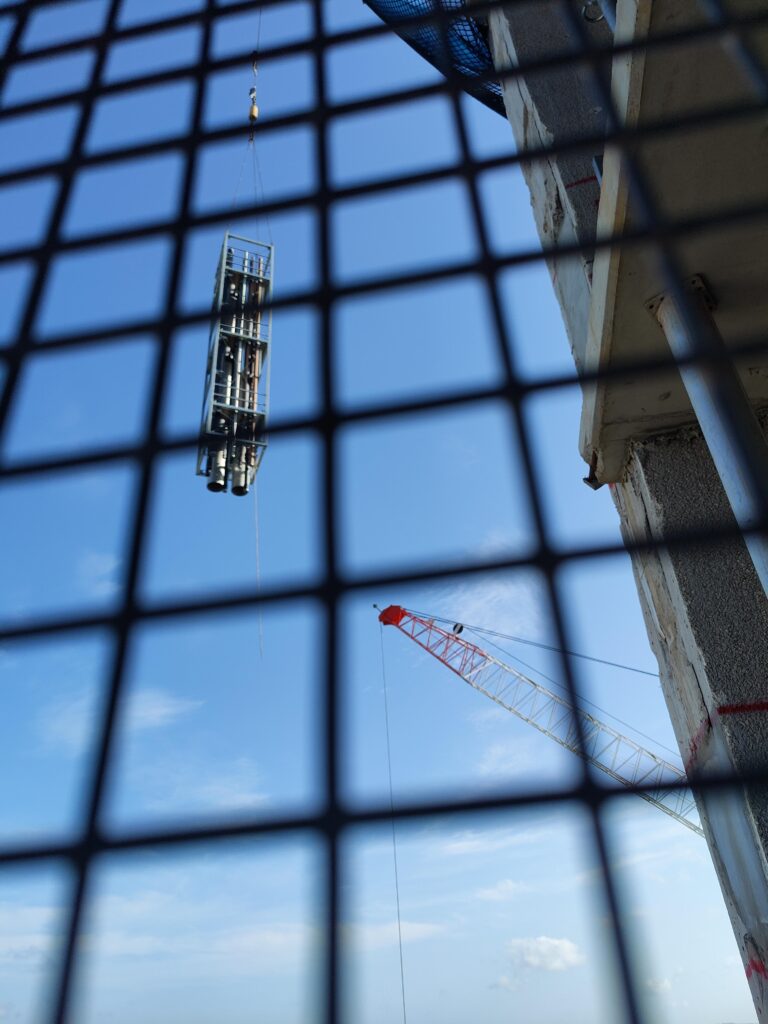

Modules were transported horizontally, rotated in mid-air using two tower cranes, and then lowered into position within the riser shaft. All lifting and placement engineering was signed off in the workshop prior to delivery to ensure safety and a smooth install.

Pipework design for building movement

KUSCH engineered riser pipework to accommodate a full range of building movements, including:

- Thermal expansion (up to 80°C fluids)

- Gravity and seismic actions

- Core shortening and inter-storey drift

For larger diameter pipes, such as the 600 mm condenser water riser, hinged expansion bellows were used to accommodate thermal growth while eliminating pressure thrust at critical anchor points. In other areas, KUSCH applied slide guides and calculated anchor positioning to avoid unnecessary bellows installation and reduce cost, complexity and maintenance requirements.

Seismic compliance and restraint certification

All pipework, frames and anchor systems were engineered and certified to meet AS1170.4 seismic requirements. Bracing and movement restraints were detailed in fabrication drawings to support practical installation. Coordination with ECJV and site teams ensured compliant, buildable outcomes.

Project Outcomes

- 200m of continuous risers installed safely within a retained tower structure.

- Reduced shaft installation risks, crane time and on-site labour with 12m long riser modules.

- Seamless integration of prefabrication with BIM workflows

- Seismic and structural compliance across pipe and frame systems

- Long-term access built into the solution through integrated platforms

Smart engineering for a complex build

At Quay Quarter Tower, KUSCH delivered more than risers. Our team provided engineering that respected the complexity of adaptive reuse, the demands of prefabrication and the constraints of one of Sydney’s most logistically challenging sites.

These services systems are largely hidden from view, but they are essential to the building’s long-term performance. Through careful coordination, innovative design and robust engineering, KUSCH played a key role in ensuring QQT performs as well as it looks.

Capabilities Demonstrated

- Seismic design of mechanical and hydraulic systems

- Pipework movement engineering

- Modular riser and access frame design

- BIM modelling and prefabrication coordination

- Lifting, anchoring and restraint certification

Interested in learning how KUSCH can help you on your next project? Contact our team today.