Anchoring to Hollowcore: Why Building Services Get Stuck Below the Slab

BackHollowcore concrete slabs offer real benefits to builders and developers – speed, efficiency, and reduced weight. But when building services contractors arrive to install ductwork, cable trays or pipework, those same slabs can quickly become a problem.

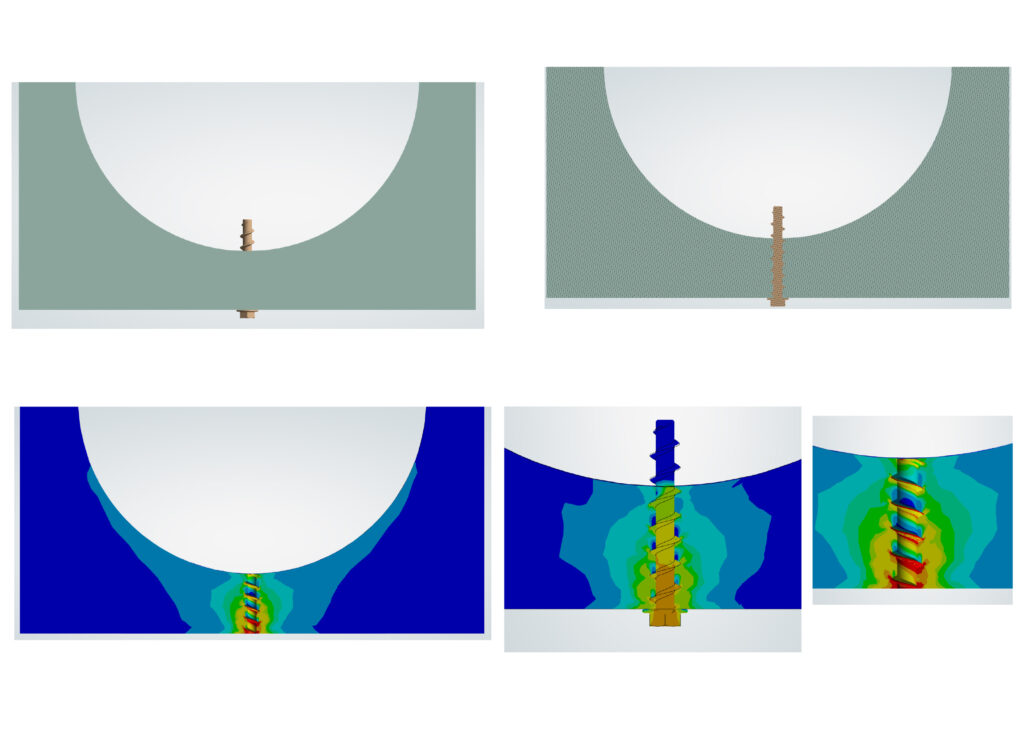

Despite their appearance, Hollowcore slabs aren’t solid concrete. And this introduces a series of challenges when it comes to anchoring services to the soffit. In many cases, these challenges aren’t properly considered during design, and the consequences are only discovered once construction is well underway.

The Challenge with Hollowcore

Most Hollowcore panels are pre-tensioned concrete units with internal voids that reduce weight and cost. The problem is those voids severely restrict the available concrete for anchoring fixings. Unlike solid slabs, there’s minimal cover, no consistent substrate, and very little margin for error.

There are three major constraints:

- Limited Embedment Depth

Prestressing strands sit close to the soffit, which prevents deep embedment. This immediately rules out many standard anchors, particularly those relying on expansion. - Void Interference

The anchor may unintentionally terminate within a void, creating a fixing that appears secure, but offers little real strength. - Compliance Issues

Mechanical anchors typically aren’t tested or rated for use in Hollowcore. Achieving seismic compliance (AS 1170.4), fire rating, and long-term durability requires more than just a ‘best guess’ fixing.

The Design Oversight

Building services are often treated as secondary elements in structural design. Hollowcore slabs get specified for their efficiency, without adequate thought given to what will be fixed to them.

This creates a compliance gap. When it’s time to anchor seismic bracing, suspended pipework or electrical systems, installers discover it’s difficult to achieve the necessary load ratings, especially under seismic, wind, or fire design conditions.

By the time this is discovered, slab panels have been installed, services are on site, and the project timeline is already under pressure.

What Can Be Done

There are very few off-the-shelf solutions that satisfy the full set of compliance requirements for anchoring into Hollowcore.

In practice, this often means:

- Engineering a performance solution for each anchor scenario

- Introducing supplementary steelwork to carry loads away from the hollow panel

- Or re-routing services to connect into structural elements designed to take the load

All of these add time and cost, unless they’re addressed early in the design phase.

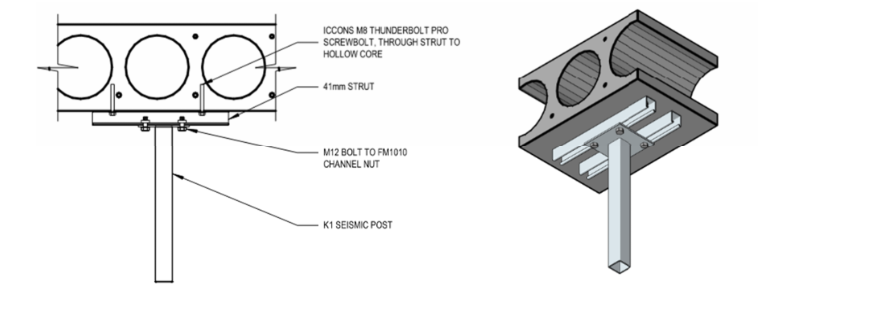

Example Fixing Detail Above: Detail shows fixed posts to the hollowcore, with strut to allow anchors to be installed in the thick section of panel, while missing the post tensioned strands.

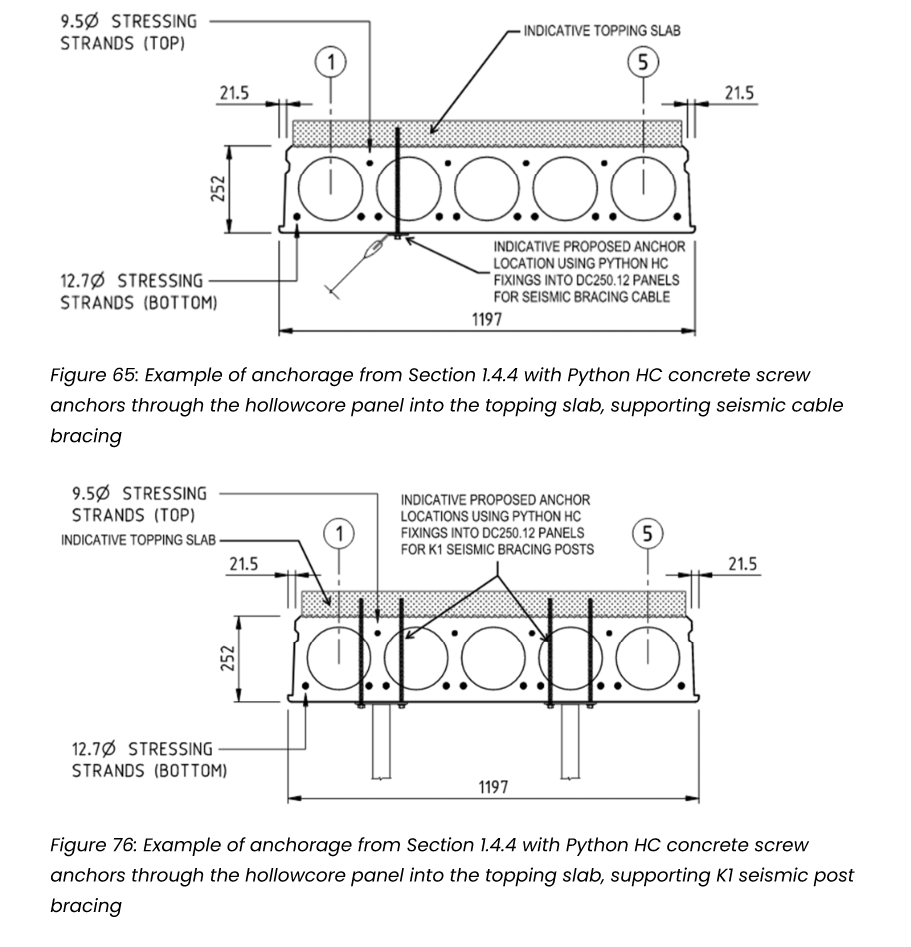

Example Fixing Detail Above: In some cases the topping slab was used with long anchors passing all the way through the hollowcore

Coordinating Fixing Strategy with Structural Design

This isn’t just a contractor problem. Structural engineers and building designers need to consider service anchorage as part of the structural layout. If Hollowcore is chosen, there needs to be a clear, compliant strategy for fixing services.

At KUSCH, we work with both design teams and contractors to develop certified anchor performance solutions, helping to avoid non-compliance and costly rework. We’ve seen the complications firsthand, and we know what works.

Key Takeaways/TLDR:

- Regular fixings aren’t designed to be used in Hollowcore slabs. Without engineering, anchors may be non-compliant or fail under load.

- Early coordination is essential. Structural design must accommodate service loads from the start.

- KUSCH provides anchor design solutions for Hollowcore applications, helping ensure compliance across seismic, structural and fire safety requirements.

If your project involves Hollowcore and suspended services, it’s worth getting the fixing strategy resolved before you start on site. Because once the slabs are in, your options are limited – and expensive.